© 2009 - 2021 Orbit Design 290 Pratt St. Meriden, CT 06450 - Call: (203) 393-0171

Orbit Design Products

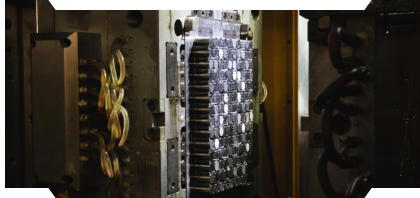

Orbit Design Tooling and Molding

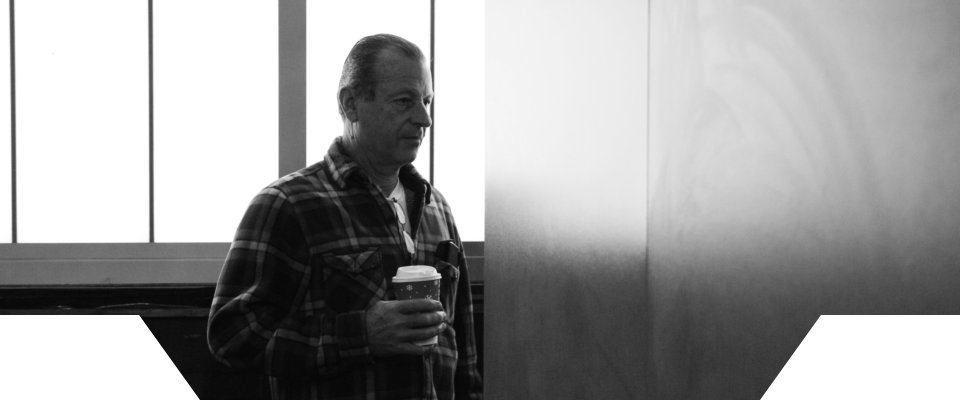

Unlike most plastics molding companies, Orbit Design makes its own molds. Full integrating the tooling and manufacturing functions allows Orbit Design to offer such extraordinary customer benefits as our tooling guarantee. For most products we make, Orbit Design will guarantee the tool for the life of the product. Customers no longer need to worry about the tooling repair cost, delays and freight charges. Speed is another benefit. Orbit Design’s process is devoid of shipping delays. We can have your job up and running faster than the most of all our competitors. Your tooling will be professionally maintained and repaired by toolmakers, not press operators. However, should a tool ever need repair, loos of your valuable production time is minimized. Our estimated turnaround time is from 2 to 48 hours for most mold repairs. Orbit Design also builds tooling for other plastic molding companies. Some of the best-known names in the industry have their injection, compression, and transfer plastic molds built by us.Continued…

Accuracy and efficiency are enhanced because we build tools specifically matching the setup procedures and capabilities of our injection molding machine and our operators. Also, Orbit Design takes a practical approach to your job and no tool will be built any more complexly or expensively than your job requires. However, we do have the ability to build up to Grade 1 tools.Orbit Design Pastic Injection Molding

Orbit Design operates a variety of computerized injection molding machines, currently ranging from 50 to 550 tons. Also offered is an array of ultra-sonic welding, secondary operations, and assembly capabilities, specializing in highly engineered parts as, we can meet the needs for the most demanding applications in such industries as computer, medical, aerospace, automotive and others. Today, Orbit Design still excels in making the most difficult plastic parts, fearing no dimensional tolerance or material. We constantly strive to remain on the cutting edge of today’s technology by using the latest innovative processes and equipment. Examples that we are currently using are in-mold decorating and over molding. Here, at Orbit Design, we believe that we must continue to evolve and incorporate the latest in today’s technological advances to meet the complex needs of our customers.

Out this World Innovation in Plastic Molding and Tooling!

© 2009 - 2021 Orbit Design 290 Pratt St. Meriden, CT 06450

Call: (203) 393-0171

Orbit Design Products

Orbit Design Tooling and

Molding

Unlike most plastics molding companies, Orbit Design makes its own molds. Full integrating the tooling and manufacturing functions allows Orbit Design to offer such extraordinary customer benefits as our tooling guarantee. For most products we make, Orbit Design will guarantee the tool for the life of the product. Customers no longer need to worry about the tooling repair cost, delays and freight charges. Speed is another benefit. Orbit Design’s process is devoid of shipping delays. We can have your job up and running faster than the most of all our competitors. Your tooling will be professionally maintained and repaired by toolmakers, not press operators. However, should a tool ever need repair, loos of your valuable production time is minimized. Our estimated turnaround time is from 2 to 48 hours for most mold repairs. Orbit Design also builds tooling for other plastic molding companies. Some of the best-known names in the industry have their injection, compression, and transfer plastic molds built by us.Continued…

Accuracy and efficiency are enhanced because we build tools specifically matching the setup procedures and capabilities of our injection molding machine and our operators. Also, Orbit Design takes a practical approach to your job and no tool will be built any more complexly or expensively than your job requires. However, we do have the ability to build up to Grade 1 tools.Orbit Design Pastic Injection

Molding

Orbit Design operates a variety of computerized injection molding machines, currently ranging from 50 to 550 tons. Also offered is an array of ultra-sonic welding, secondary operations, and assembly capabilities, specializing in highly engineered parts as, we can meet the needs for the most demanding applications in such industries as computer, medical, aerospace, automotive and others. Today, Orbit Design still excels in making the most difficult plastic parts, fearing no dimensional tolerance or material. We constantly strive to remain on the cutting edge of today’s technology by using the latest innovative processes and equipment. Examples that we are currently using are in-mold decorating and over molding. Here, at Orbit Design, we believe that we must continue to evolve and incorporate the latest in today’s technological advances to meet the complex needs of our customers.

Out this World Innovation in

Plastic Molding and Tooling!